Choosing the right switchgear power system can be a daunting task. Many factors influence this decision. It is essential to understand your specific needs before diving in. A reliable switchgear system ensures safety and efficiency in electrical installations.

Consider the voltage level and load capacity of your system. Different applications, from industrial to commercial, require unique specifications. Investing time in research can yield better results. Overlooked details may lead to costly mistakes in the long run.

Moreover, it's crucial to evaluate the reputation of manufacturers. Not all products meet high-quality standards. Make sure to ask the right questions during your consultation. A well-chosen switchgear power system enhances performance and longevity. Ultimately, making a mindful choice today will pay off in the future.

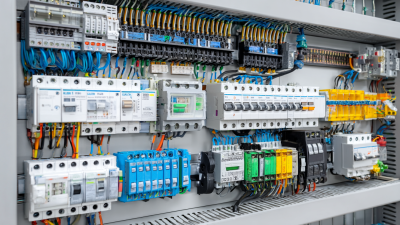

Switchgear power systems are essential components in electrical networks. They act as the backbone for controlling, protecting, and isolating electrical equipment. Understanding these systems is crucial for effective energy distribution. According to a recent industry report, the global switchgear market is expected to reach $130 billion by 2027. This growth emphasizes the importance of selecting the right system for specific needs.

When choosing switchgear, consider the voltage level. High-voltage switchgear is used for transmission, while low-voltage options are preferable for distribution. Additionally, assess the operational environment. Factors like temperature, humidity, and location impact performance. A study from the International Electrotechnical Commission suggests that nearly 30% of switchgear failures result from environmental conditions.

Tips: Always analyze your load requirements thoroughly. Underestimating capacity can lead to system overloads. Regular maintenance schedules are also vital. Neglecting this can cause unforeseen failures. When making decisions, seek input from multiple experts. Diverse perspectives often reveal overlooked aspects. Balancing performance with cost can also be challenging. Aim for long-term reliability over immediate savings.

This bar chart provides an overview of different types of switchgear power systems and their typical applications. The data showcases the percentage of use per system type based on industry standards and trends.

When choosing the right switchgear power system, knowing your power requirements is crucial. Start by assessing your total load demand. Consider both continuous and peak loads. Different applications have varying needs. For instance, a manufacturing plant may require higher loads during operation hours. In contrast, a small office may have steadier, lower demands.

Tips: Monitor your energy consumption regularly. This helps to adjust your system according to real needs.

Understand the load types. Are they resistive, inductive, or capacitive? Each type affects your switchgear selections. Resistive loads are straightforward. However, inductive loads can cause spikes in power demand. Pay attention to how your equipment operates. This insight will guide your decisions effectively.

Tips: Review historical load data to predict future needs. Don't underestimate sudden increases in power usage.

Finally, reflect on your future growth. Are you planning to expand? Your switchgear should accommodate potential additions. A system that's too small can lead to failures or inefficiencies. Always think ahead and create flexibility in your setup. This will ensure that you meet both current and future requirements efficiently.

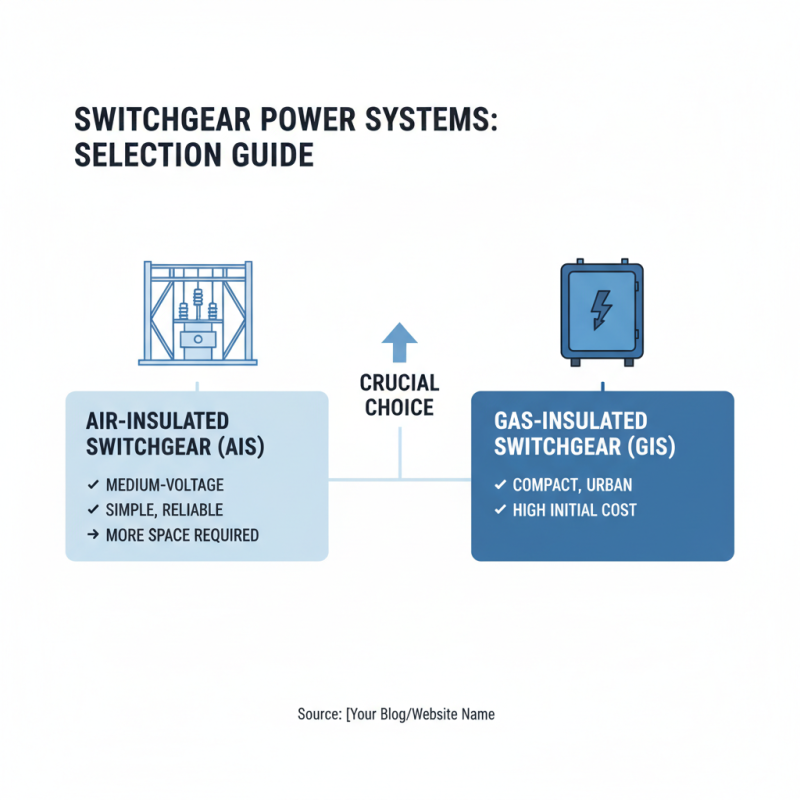

Choosing the right switchgear power system is crucial. Different types of switchgear serve unique applications. For instance, air-insulated switchgear (AIS) is common in medium-voltage systems. It offers simplicity and reliability, yet it occupies more space compared to other types. In contrast, gas-insulated switchgear (GIS) is compact and suitable for urban settings. However, its initial cost can be substantially higher.

Evaluating switchgear types involves assessing their efficiency and safety. According to the latest industry reports, over 30% of power outages are linked to outdated equipment. For instance, modern switchgear can enhance system reliability by up to 20%. Furthermore, switchgear plays a critical role in grid stability and fault management. However, organizations often overlook the need for regular maintenance and upgrades. Ignoring this can lead to operational inefficiencies and increased long-term costs.

The applications of switchgear extend across renewable energy, industrial sectors, and commercial buildings. With the rise of renewable energy sources, the demand for advanced switchgear types is growing. Notably, digital switchgear is gaining traction, allowing for real-time monitoring and enhanced communication. However, transitioning to these systems poses a significant challenge for many facilities, often due to budget constraints and technical expertise. Investing time to evaluate these needs critically can prevent future headaches.

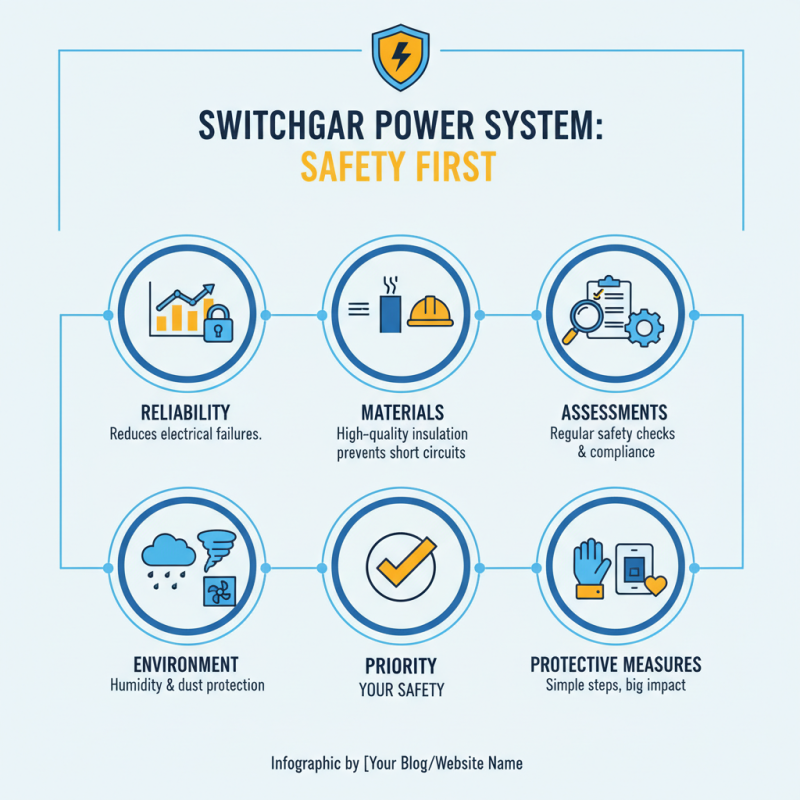

When choosing a switchgear power system, safety should be a top priority. A reliable system reduces the risk of electrical failures. It’s crucial to assess the construction materials used. High-quality insulation can prevent short circuits. Regular safety assessments are necessary to ensure compliance. Consider the environment, too. Humidity and dust can impact performance. Simple protective measures can make a huge difference.

Maintenance considerations cannot be overlooked. A good system allows for easy access to components. This facilitates regular checks and repairs. Trained personnel should conduct these maintenance tasks. Look for systems requiring minimal downtime. A poorly maintained switchgear can lead to serious issues. Reflect on your operation needs; they determine the maintenance schedule. Some systems may look reliable but can be problematic without proper upkeep. Balancing reliability and maintenance can be challenging but is essential for long-term success.

When budgeting for switchgear power systems, understanding costs is crucial. According to industry reports, installation can account for 30-50% of the total investment. Total expenditures should include both equipment and labor costs. Many professionals overlook this in their projections.

Maintenance costs may also surprise you. Regular inspections and repairs are necessary. Budgeting for these ongoing expenses can save money in the long run. Studies indicate that neglecting maintenance can lead to system failures. These failures can cost 5 to 10 times more than regular upkeep.

Consider future scalability when analyzing your budget. Many systems require upgrades as demand increases. Initial cost savings might tempt you to choose an underpowered system. However, that could lead to more frequent replacements or upgrades. It's essential to weigh short-term savings against long-term functionality. Remember, the most cost-effective solution is not always the cheapest one upfront.

| Dimension | Cost Estimate (USD) | Expected Lifespan (Years) | Maintenance Frequency (Annual) | Power Rating (kVA) |

|---|---|---|---|---|

| Low Voltage Switchgear | $5,000 - $15,000 | 20 | 1 | 100-500 |

| Medium Voltage Switchgear | $15,000 - $50,000 | 25 | 1-2 | 500-2000 |

| High Voltage Switchgear | $50,000 - $150,000 | 30 | 2-3 | 2000-5000 |

| Customized Switchgear Solutions | $20,000 - $200,000 | 20+ | Varies | Varies |