In today's world, managing a switchgear power system is vital for ensuring energy reliability and efficiency. Industry expert Dr. Emily Chen has emphasized, "A well-managed switchgear power system can prevent extensive failures and costly downtime." This quote highlights the necessity of proper management.

Switchgear systems play a crucial role in electrical distribution. Yet, many organizations struggle with their upkeep. They often overlook routine inspections, leading to potential hazards. The intricacies of these systems require both knowledge and diligence.

In a rapidly evolving industry, the need for skilled management rises. Technological advancements provide tools for better oversight. However, human error remains a concern. Teams must prioritize training and awareness. Without it, even the best systems can falter. Understanding the importance of switchgear power systems is just the first step.

Switchgear power systems play a crucial role in the distribution and control of electrical power. These systems ensure that electrical circuits are efficiently managed. Understanding their basics is essential for effective operation and maintenance. According to a recent industry report, investment in switchgear technology is projected to grow at a rate of 5% annually, driven by increasing demand for reliable power supply.

Managing switchgear systems involves careful attention to various factors. One tip is to conduct regular maintenance checks. This helps identify potential issues before they escalate. Regular inspections can reduce unforeseen downtime and enhance system reliability. Another key point is to invest in training for personnel. Knowledgeable staff are less likely to make operational errors that can lead to equipment failure.

Switchgear systems can be complex. Operators often face challenges in monitoring performance. Keeping detailed records of system parameters can improve understanding. It’s essential to analyze this data to spot trends or recurring problems. Be aware that minor issues can lead to significant failures if ignored. Regularly reviewing these records is a proactive approach for better management.

Switchgear is crucial for controlling electrical power systems. Understanding its key components helps manage these systems effectively. Circuit breakers play a vital role. They protect equipment from overloads and short circuits. When a fault occurs, they disconnect power quickly. This prevents further damage and enhances safety.

Another essential component is the switch. Switches regulate the flow of electricity. They allow operators to isolate sections of the system for maintenance. This function is critical for ensuring the safety of technicians. Additionally, busbars serve as power distribution points. They connect multiple circuits, enabling efficient power management. Sometimes, they can become points of failure if not properly maintained.

Fuses are also important. They safeguard against excessive current flow. Once they blow, they need to be replaced promptly. Delaying this can lead to larger issues down the line. Monitoring every component regularly can sometimes feel overwhelming. Yet, it is necessary for optimal performance. Inadequate attention can escalate minor issues into significant challenges.

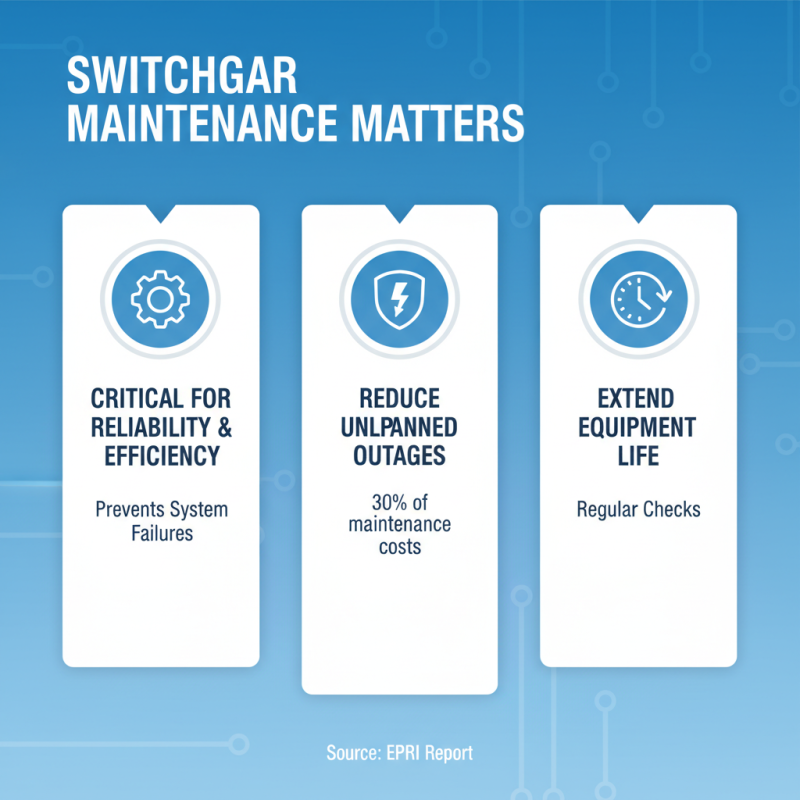

Routine maintenance of switchgear systems is critical for ensuring reliability and efficiency. According to a report by the Electric Power Research Institute, nearly 30% of maintenance costs can be attributed to unplanned outages. This emphasizes the need for vigilant care. Regular checks help prevent system failures and extend equipment life.

One essential tip is to conduct thermal imaging inspections. This method identifies overheating issues early. Overheating can lead to significant damage and costly repairs. Additionally, ensure that all connections are tight. Loose connections can create resistance and generate heat, resulting in inefficient performance.

Another important practice is performing insulation resistance tests. A report by the Institute of Electrical and Electronics Engineers states that nearly 25% of equipment failures are due to insulation issues. Testing insulation not only aids in preventing failures but also enhances safety. Regular cleaning and dusting of switchgear components is a practical step too; it reduces potential hazards and improves airflow. These small yet crucial tasks often get overlooked but can make a significant difference in the long run.

When working with high voltage switchgear, safety must be the priority. Always wear appropriate personal protective equipment, including gloves and goggles. These items protect against electrical shocks and arc flashes. Ensure all team members understand the risks associated with high voltage areas. Communication can prevent accidents.

Before starting any work, conduct a thorough inspection of the switchgear. Look for wear and tear, and proper insulation. This step helps identify potential hazards. Always de-energize equipment before handling. Use lockout/tagout procedures to prevent accidental re-energization. This practice is crucial but often overlooked, leading to dangerous situations.

Finally, maintain a clean and organized work area. Clutter can cause distractions and increase the risk of mistakes. Always have an emergency response plan in place. Discuss scenarios with the team. Reflect on previous incidents to improve safety protocols. Sharing experiences can lead to better practices and a safer environment.

Switchgear operations are critical for maintaining electrical safety and reliability. However, issues can arise unexpectedly. Understanding common problems is essential for effective troubleshooting. One frequent issue is improper grounding. Inadequate grounding can lead to dangerous electrical faults. Regular inspections should be conducted to check grounding systems.

Another common concern is the failure of insulation. Moisture or contamination can degrade insulation. This can result in short circuits or equipment damage. Visual inspections can identify obvious signs, but a more detailed electrical testing is ideal. Keep an eye out for discoloration or physical damage.

Equipment overheating can also pose significant risks. Poor ventilation may be a factor. Ensure that switchgear components are well-ventilated and free of obstructions. Regular cleaning is crucial to remove dust and debris, helping maintain optimal performance. Addressing these issues requires ongoing attention and careful monitoring. Each problem solved can lead to better reliability and efficiency in switchgear operations.