In today's fast-paced business environment, maintaining operational efficiency is crucial for success. One of the often-overlooked aspects that can significantly impact a company's overall performance is the quality of power supplied to its facilities. This is where a robust power quality management system comes into play. By monitoring and managing the quality of electricity, businesses can mitigate risks such as equipment malfunctions, downtime, and operational disruptions that stem from power quality issues.

A power quality management system not only enhances the reliability of electrical systems but also ensures optimal performance of machinery and technology, translating to higher productivity levels. With the increasing reliance on sophisticated electronic equipment across various industries, understanding and addressing power quality issues is more important than ever. Such a system provides valuable insights into voltage fluctuations, harmonics, and other electrical parameters, enabling businesses to make informed decisions that align with their operational goals.

Ultimately, implementing an effective power quality management system is essential for any organization looking to improve business efficiency. By prioritizing power quality, companies can protect their assets, enhance their service delivery, and gain a competitive edge in the market. Embracing this proactive approach not only safeguards operational continuity but also fosters a culture of reliability and excellence within the organization.

Power Quality Management Systems (PQMS) are essential tools that ensure the efficiency and reliability of electrical power in a business environment. A PQMS monitors and manages the quality of electrical power, helping to minimize disturbances such as voltage sags, surges, and harmonics that can negatively impact equipment performance and operational efficiency. By maintaining optimal power quality, businesses can reduce downtime, lower energy costs, and enhance overall productivity.

Implementing a robust PQMS is crucial not only for protecting equipment but also for enhancing the longevity of machinery and extending the lifecycle of electrical assets. Poor power quality can lead to premature equipment failure, costly repairs, and increased maintenance efforts. In contrast, businesses with effective power quality management can experience smoother operations and improved service delivery, leading to greater customer satisfaction.

Tips: Regularly conduct power quality assessments to identify potential issues before they escalate. Invest in training for staff to recognize the signs of power quality problems, and encourage proactive maintenance routines that include regular monitoring of electrical systems. Additionally, consider utilizing advanced technology to automate power quality correction measures, ensuring your business remains resilient against power disturbances.

An effective Power Quality Management System (PQMS) is crucial for enhancing business efficiency by ensuring stable and reliable electrical supply. The primary components of a PQMS include monitoring and diagnostic tools, power conditioning devices, and management strategies. Monitoring tools help in continuously assessing the quality of power, identifying disturbances such as voltage sags, surges, and harmonics. By equipping systems with real-time data tracking, businesses can preemptively address potential issues before they escalate, reducing unnecessary downtime.

Another essential component is the use of power conditioning solutions which mitigate disturbances and enhance the quality of electrical supply. These devices include voltage regulators, surge protectors, and harmonic filters. Implementing these tools can protect sensitive equipment from damage, prolong its lifespan, and improve overall operational reliability.

**Tips:** Regularly conducting power audits can help businesses identify areas of improvement within their PQMS. They should also invest in training staff on power quality issues to foster a culture of awareness and proactive problem-solving. Engaging with energy consultants can provide further insights into optimizing power use and improving system resilience.

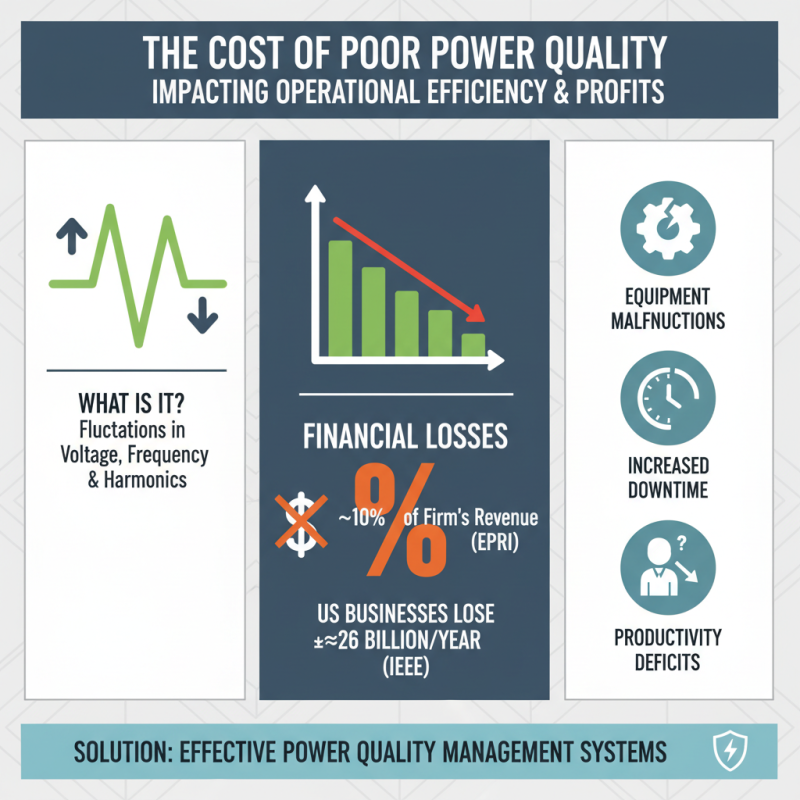

Power quality plays a crucial role in determining operational efficiency within various industries. According to the Electric Power Research Institute (EPRI), poor power quality can lead to significant financial losses, averaging about 10% of a firm’s revenue. Fluctuations in voltage, frequency disturbances, and harmonics can result in equipment malfunctions, increased downtime, and deficits in productivity. For instance, a study by the Institute of Electrical and Electronics Engineers (IEEE) found that businesses lose approximately $26 billion annually in the United States due to power quality issues, highlighting the pressing need for effective power quality management systems.

Implementing a robust Power Quality Management System (PQMS) can mitigate these risks and foster cost savings. The International Electrotechnical Commission (IEC) suggests that companies actively engaging in power quality management can achieve operational cost reductions of 15-20%. By optimizing energy use, preventing equipment failures, and minimizing unplanned outages, businesses can enhance their overall efficiency. Moreover, a report from Navigant Research indicates that organizations focusing on energy management, including power quality, can reduce their energy expenses by as much as 30%. This demonstrates that prioritizing power quality is not just a technical necessity but a strategic financial decision that can yield significant economic benefits.

Power quality issues are a significant concern for businesses, impacting not only their operational efficiency but also their financial performance. According to a report by the Electrical Power Research Institute (EPRI), businesses in the United States lose about $150 billion annually due to power quality-related problems. Voltage sags, surges, and transients can disrupt production processes, leading to increased downtime and operational disruptions. In fact, a survey conducted by the Institute of Electrical and Electronics Engineers (IEEE) found that 80% of companies experience power quality issues that result in losses averaging $14,000 per hour.

The financial implications of power quality issues extend beyond direct losses. The National Renewable Energy Laboratory (NREL) has estimated that the total cost of poor power quality can exceed $100 billion annually when considering the cumulative effects on equipment lifespan, maintenance costs, and energy efficiency. Moreover, a study by the International Energy Agency (IEA) indicated that companies investing in power quality management systems see up to a 30% improvement in equipment lifespan and a significant reduction in maintenance costs. By proactively addressing power quality, businesses can not only enhance their operational efficiency but also realize substantial long-term savings.

| Issue | Impact on Business (Annual) | Percentage of Businesses Affected | Estimated Cost (USD) |

|---|---|---|---|

| Voltage Sags | Production Downtime | 30% | $50,000 |

| Harmonics | Equipment Damage | 25% | $30,000 |

| Voltage Swells | Operational Disruption | 20% | $40,000 |

| Transients | Equipment Repair Costs | 15% | $60,000 |

| Power Factor Issues | Increased Energy Costs | 35% | $20,000 |

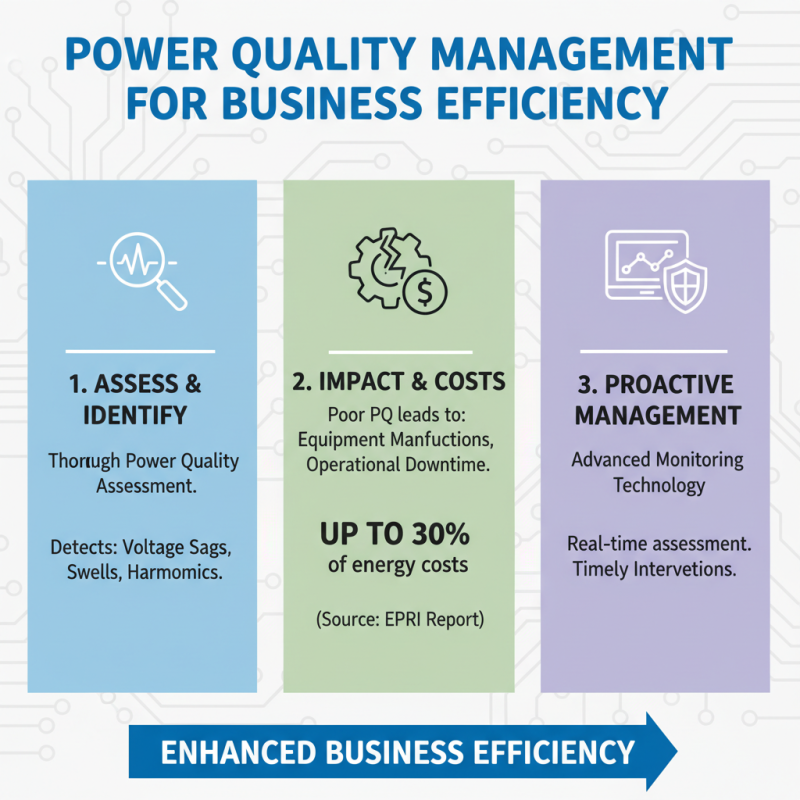

Implementing a Power Quality Management (PQM) system is vital for enhancing business efficiency. One of the best practices is conducting a thorough power quality assessment to identify issues such as voltage sags, swells, or harmonics. According to a report by the Electric Power Research Institute (EPRI), poor power quality can lead to equipment malfunctions, resulting in significant operational downtime and costs that can reach up to 30% of a business's total energy expenses. By utilizing advanced monitoring technology, businesses can assess their power quality issues in real time, allowing for proactive management and timely interventions.

Another key aspect of effective PQM implementation is staff training and awareness. Employees should be educated on the impact of power quality on business operations and the importance of maintaining a stable electrical environment. Training programs can enhance employees' ability to identify potential power quality problems and encourage them to report anomalies promptly. Data from the International Electrotechnical Commission indicates that unaddressed power quality issues can lead to an increase in energy consumption by as much as 20%, emphasizing the importance of integrated training and awareness initiatives. By fostering a culture of vigilance and responsiveness around power quality, businesses can significantly boost their efficiency while also ensuring the longevity of their equipment.